3D printing, also known as additive manufacturing, has transformed from a niche technology into a cornerstone of innovation by 2025. This revolutionary process, which builds objects layer by layer from digital designs, is reshaping industries, from manufacturing to healthcare, and even personal creativity. With advancements in materials, speed, and accessibility, 3D printing is democratizing production, enabling customization, and addressing global challenges like sustainability and supply chain resilience. This 3000-word post explores the history, current state, applications, societal impacts, future prospects, and challenges of 3D printing, providing a comprehensive overview of its role in 2025. Structured with clear headings and enriched with three image prompts, this article dives deep into the world of additive manufacturing.

Introduction to 3D Printing

3D printing is a process that creates three-dimensional objects by depositing materials—such as plastics, metals, or biomaterials—layer by layer based on digital models. Unlike traditional subtractive manufacturing, which cuts material away, additive manufacturing minimizes waste, making it both efficient and sustainable. In 2025, the global 3D printing market is valued at over $30 billion, with a projected growth rate of 20% annually, driven by innovations in multi-material printing and industrial-scale applications.

The technology’s appeal lies in its versatility. From prototyping to producing end-use parts, 3D printing serves industries like aerospace, automotive, healthcare, and consumer goods. It empowers individuals to create custom products at home, while corporations use it to streamline production. However, challenges like scalability, material limitations, and intellectual property concerns persist. This post delves into the evolution, key applications, and transformative potential of 3D printing, while addressing its hurdles and future directions.

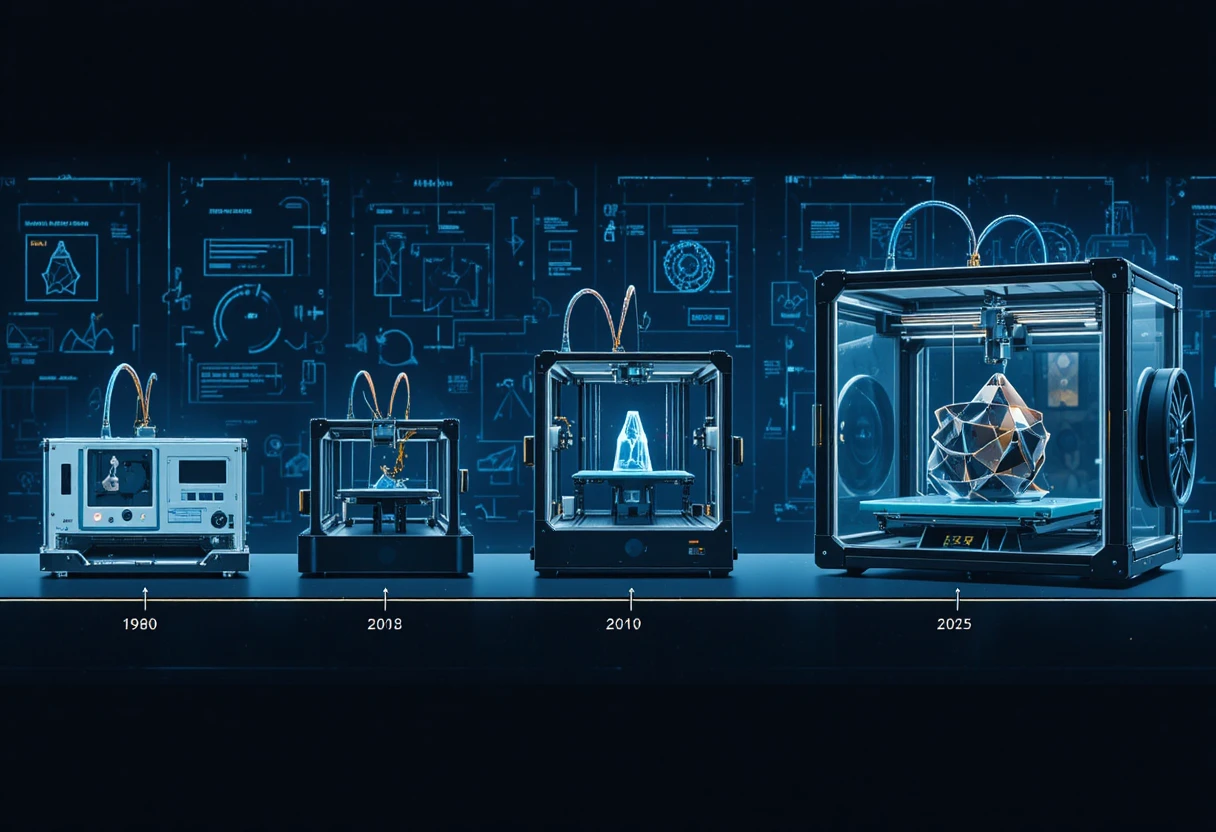

History and Evolution of 3D Printing

Early Beginnings

3D printing’s origins trace back to the 1980s. In 1984, Chuck Hull invented stereolithography (SLA), the first 3D printing technology, which used UV light to cure liquid resin into solid objects. Hull’s company, 3D Systems, commercialized the first 3D printer in 1986. Around the same time, selective laser sintering (SLS) and fused deposition modeling (FDM) emerged, expanding the range of materials from resins to plastics and powders.

In the 1990s, 3D printing was primarily used for rapid prototyping, allowing engineers to test designs without costly molds. The technology was expensive, with industrial printers costing hundreds of thousands of dollars, limiting its use to large corporations. The early 2000s saw advancements in precision, enabling applications in aerospace and medical devices.

The Democratization of 3D Printing

The turning point came in 2009 with the expiration of key FDM patents, sparking the open-source RepRap project. This initiative, led by Adrian Bowyer, aimed to create self-replicating 3D printers, drastically reducing costs. By 2010, desktop 3D printers like the MakerBot Replicator were available for under $2,000, bringing the technology to hobbyists and small businesses.

The 2010s saw exponential growth. Companies like Stratasys and Formlabs introduced high-precision printers, while material science advancements enabled printing with metals, ceramics, and biocompatible materials. By 2020, 3D printing was used in mass production, with General Electric manufacturing jet engine parts and Adidas creating 3D-printed shoe soles.

In 2025, 3D printing is faster, more affordable, and integrated with AI for optimized designs. Multi-material printers can combine metals and plastics in a single print, while large-scale systems construct entire buildings. The technology’s accessibility has made it a staple in classrooms, maker spaces, and even homes.

Key Technologies and Processes

Types of 3D Printing Technologies

3D printing encompasses several techniques, each suited to specific applications:

- Fused Deposition Modeling (FDM): The most common for consumer printers, FDM extrudes melted plastic filament to form objects. Affordable and versatile, it’s used for prototypes and consumer goods but lacks precision for high-end applications.

- Stereolithography (SLA): SLA uses UV lasers to cure resin, offering high resolution for intricate designs like dental molds or jewelry.

- Selective Laser Sintering (SLS): SLS fuses powdered materials (plastic, metal, or ceramic) with lasers, ideal for durable parts in aerospace and automotive industries.

- Direct Metal Laser Sintering (DMLS): A variant of SLS, DMLS prints metal parts with precision, used for turbine blades and medical implants.

- Binder Jetting: This deposits a binding agent onto powder layers, enabling large-scale printing for sand molds or full-color models.

- PolyJet: Similar to inkjet printing, PolyJet sprays photopolymer droplets, allowing multi-material and multi-color prints in a single run.

In 2025, hybrid systems combine these methods, enabling complex, multi-functional parts. For example, HP’s Multi Jet Fusion produces parts 10 times faster than traditional SLS, revolutionizing industrial production.

Materials Advancements

Material innovation is a key driver of 3D printing’s growth. In 2025, printers handle plastics (PLA, ABS), metals (titanium, aluminum), ceramics, and biomaterials like hydrogels for tissue engineering. Carbon-fiber-reinforced composites enhance strength for automotive parts, while graphene-infused filaments improve conductivity for electronics.

Sustainable materials are gaining traction. Recycled plastics and biodegradable filaments reduce environmental impact. In food printing, edible materials like chocolate and plant-based proteins create custom meals. Metal 3D printing has advanced with alloys designed for high-temperature resistance, critical for aerospace and energy sectors.

Speed and Scale Improvements

Speed has been a bottleneck, but 2025 sees breakthroughs. Continuous Liquid Interface Production (CLIP) by Carbon3D prints 100 times faster than early SLA systems. Large-scale printers, like those from ICON, construct concrete homes in under 24 hours. AI-driven software optimizes print paths, reducing production time by 30%.

Applications of 3D Printing

Manufacturing and Industry

3D printing is revolutionizing manufacturing by enabling on-demand production and reducing reliance on global supply chains. In aerospace, Boeing and Airbus use 3D-printed titanium parts, cutting weight by 40% and fuel costs by 15%. Automotive companies like Ford produce lightweight components, improving electric vehicle (EV) efficiency.

Customization is a key advantage. Manufacturers create bespoke parts without expensive tooling, while small businesses produce limited-run products. In 2025, 3D printing accounts for 10% of global manufacturing output, per a McKinsey report, with industries saving $250 billion annually on inventory costs.

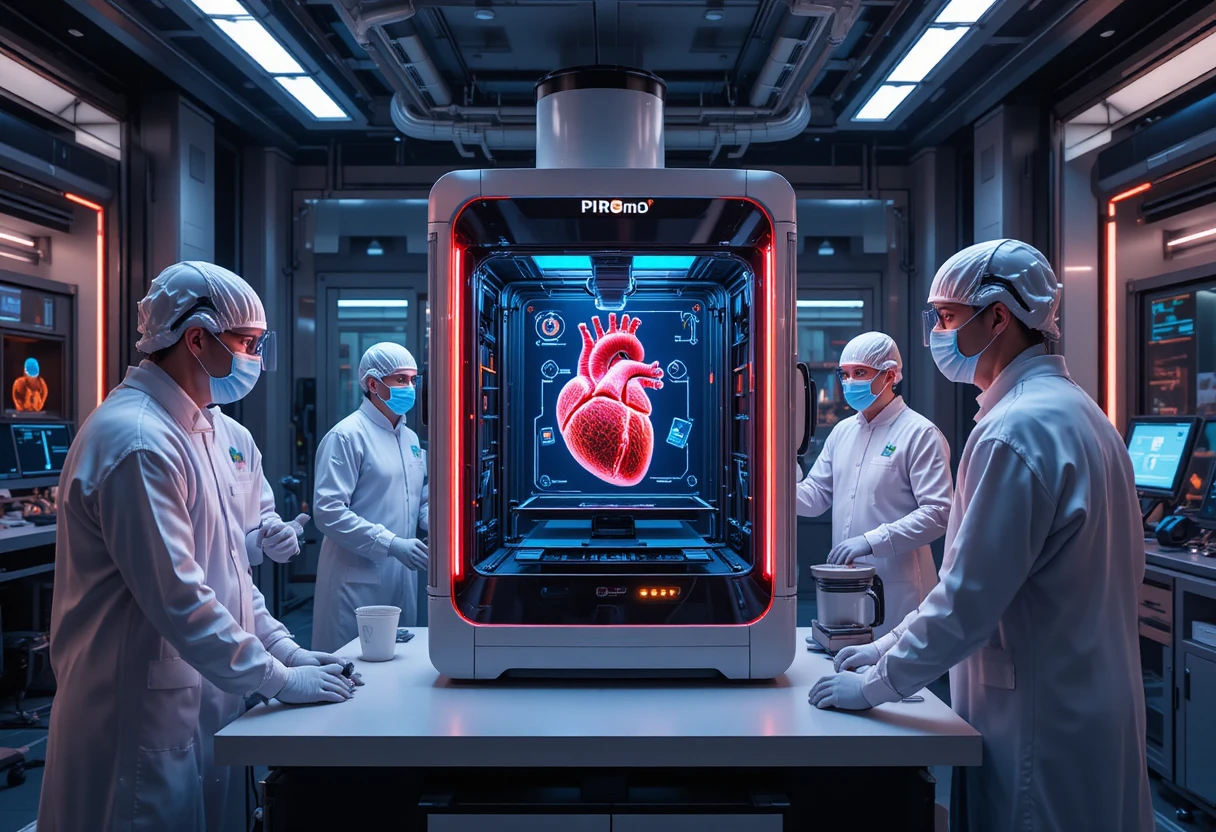

Healthcare and Bioprinting

Healthcare is one of 3D printing’s most transformative domains. Custom prosthetics and orthotics are printed to fit patients perfectly, reducing costs by 50% compared to traditional methods. Dental practices use SLA printers for crowns and aligners, with same-day delivery becoming standard.

Bioprinting is a frontier in 2025. Using bioinks made of living cells, researchers print tissues for drug testing and organ repair. Companies like Organovo have printed functional liver tissue, while startups are working on 3D-printed heart valves. In clinical trials, bioprinted skin grafts have accelerated wound healing by 60%.

Construction and Architecture

3D printing is reshaping construction. Companies like Apis Cor and ICON print concrete structures, from homes to bridges, using robotic arms. In 2025, a 500-square-foot house can be printed in 12 hours for under $20,000, addressing housing shortages in developing nations. These structures are durable, energy-efficient, and customizable.

Architectural firms use 3D printing for intricate models, while disaster relief agencies deploy portable printers to build emergency shelters. Sustainable concrete mixes, incorporating recycled materials, reduce emissions by 30% compared to traditional construction.

Consumer and Creative Applications

For consumers, 3D printing fosters creativity. Hobbyists design custom jewelry, toys, and home decor using affordable printers like the Creality Ender-7. Online platforms like Thingiverse offer millions of free designs, while Etsy sellers provide bespoke 3D-printed products.

In fashion, 3D-printed clothing and accessories, like Adidas’ 4DFWD shoes, combine style and performance. Food printing is gaining traction, with devices like Foodini creating intricate desserts or personalized nutrition plans for dietary needs.

Education and Research

3D printing enhances education by enabling hands-on learning. Schools use printers to create anatomical models, engineering prototypes, and historical artifacts, boosting STEM engagement. Universities leverage high-end systems for research, from printing microfluidic devices to testing new materials.

Societal Impacts of 3D Printing

Economic and Supply Chain Benefits

3D printing decentralizes production, reducing reliance on global supply chains exposed during the 2020s chip shortages. Local manufacturing hubs print parts on demand, cutting shipping costs and emissions. Small businesses and startups benefit from low-cost prototyping, leveling the playing field against large corporations.

Job creation is significant, with roles in design, material science, and printer maintenance growing by 25% since 2020. However, automation of traditional manufacturing jobs raises concerns, with 15% of factory roles at risk, per a 2025 World Economic Forum report.

Environmental Sustainability

3D printing promotes sustainability by minimizing waste. Unlike subtractive methods, additive manufacturing uses only the material needed, reducing scrap by up to 90%. Recycled and biodegradable materials further lower environmental impact. In construction, 3D-printed buildings use less concrete, cutting emissions.

However, energy consumption is a concern, as industrial printers require significant power. Advances in solar-powered printers and energy-efficient lasers are mitigating this, with companies like Stratasys reporting 20% energy savings in new models.

Accessibility and Customization

3D printing democratizes access to manufacturing. Individuals in remote areas print tools, medical devices, or spare parts, addressing resource scarcity. Nonprofits like e-NABLE provide 3D-printed prosthetics to underserved communities, improving quality of life.

Customization enhances user experiences. From tailored medical implants to personalized consumer goods, 3D printing meets individual needs, fostering inclusivity. In 2025, 30% of consumer electronics accessories, like phone cases, are 3D-printed, per a Gartner study.

Future Prospects of 3D Printing

By 2030, 3D printing is expected to disrupt multiple sectors further. In manufacturing, hybrid systems combining additive and subtractive methods will produce complex parts at scale. AI integration will optimize designs for strength and efficiency, reducing material use by 25%.

In healthcare, fully functional 3D-printed organs, like kidneys or livers, could become viable, addressing transplant shortages. Space exploration will benefit, with NASA planning to print habitats on Mars using local materials. Consumer printers will become as common as inkjet printers, with sub-$200 models offering multi-material capabilities.

Sustainability will advance with fully recyclable filaments and zero-waste printing processes. 4D printing, where objects change shape over time in response to stimuli like heat or water, will enable self-assembling structures for construction and medical applications.

Challenges and Considerations

Technical Limitations

Despite progress, 3D printing faces technical hurdles. Speed remains a bottleneck for mass production, though innovations like CLIP are closing the gap. Material limitations restrict applications; for instance, not all metals are printable with current systems. Surface finish and strength can lag behind traditional methods, requiring post-processing.

Scalability is another issue. While large-scale printers exist, they’re costly, limiting adoption. Precision at the nanoscale, critical for electronics, is still developing, with only a few systems offering sub-micron accuracy.

Intellectual Property and Regulation

3D printing raises intellectual property (IP) concerns. Digital designs can be easily shared or pirated, challenging traditional copyright systems. In 2025, blockchain-based platforms track design ownership, but enforcement varies globally. Regulatory gaps exist, particularly for 3D-printed medical devices and firearms, prompting calls for stricter oversight.

Environmental and Ethical Concerns

While sustainable, 3D printing’s environmental footprint isn’t zero. Plastic filaments contribute to microplastic pollution if not recycled properly. Energy-intensive processes, especially metal printing, strain grids in regions reliant on fossil fuels. Ethical concerns include the potential for 3D-printed weapons, with “ghost guns” remaining a regulatory challenge.

Accessibility and Workforce Impact

High-end printers remain expensive, limiting access for small businesses in developing regions. The digital divide affects design software proficiency, requiring investment in education. Workforce displacement is a concern, as 3D printing automates roles in manufacturing and logistics, necessitating reskilling programs.

Conclusion

In 2025, 3D printing is a transformative force, redefining manufacturing, healthcare, construction, and consumer creativity. Its ability to customize, reduce waste, and localize production makes it a pillar of innovation. However, technical, ethical, and environmental challenges require careful navigation to ensure equitable and sustainable adoption. As we look toward 2030, advancements in materials, AI integration, and 4D printing promise to push boundaries further, making 3D printing a key driver of a personalized, efficient, and sustainable future. By addressing its challenges, society can harness its full potential to solve global problems and empower individuals.